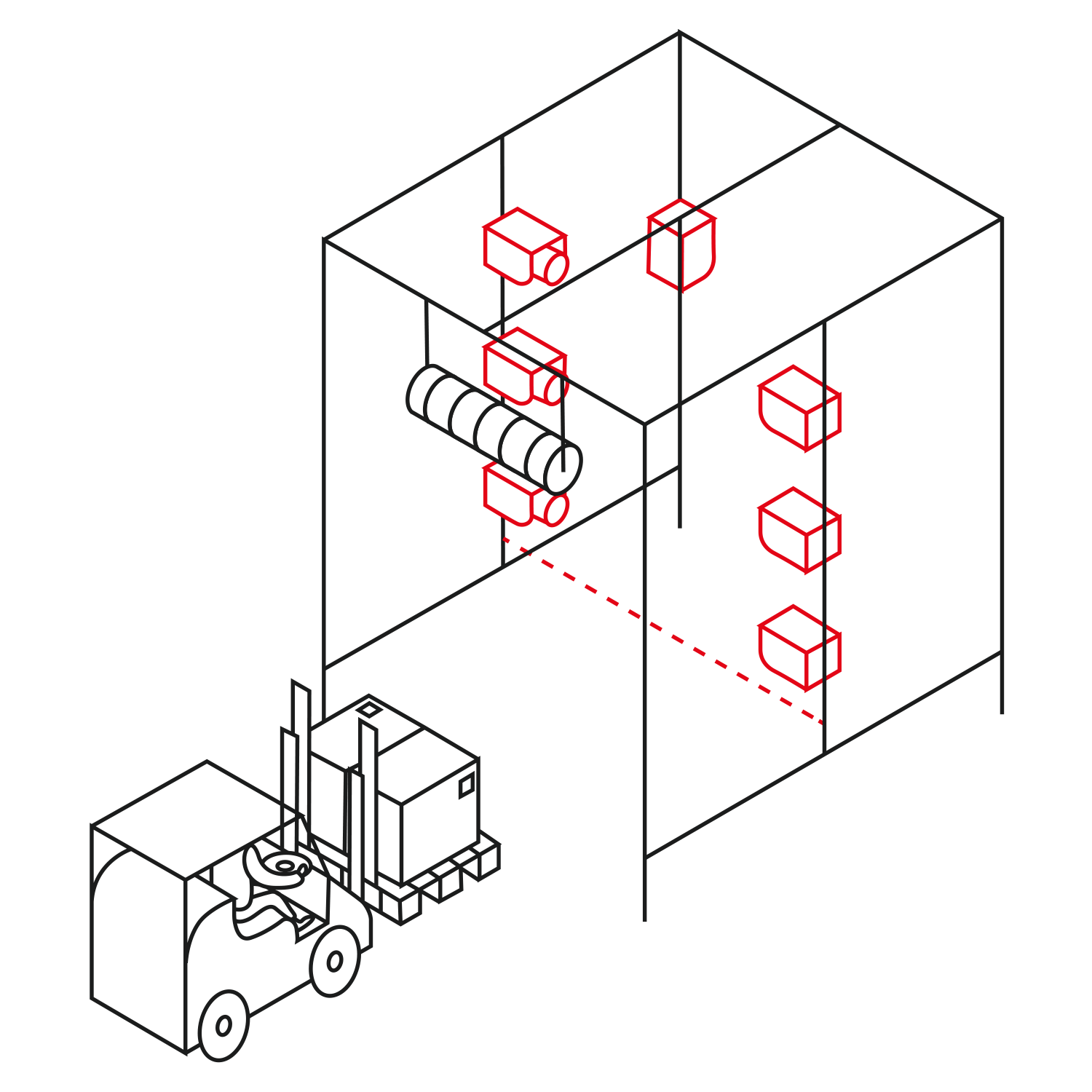

Automated temperature and safety check

Our incoming goods gate ensures a continuous checking of all incoming and outgoing goods.

Safety

The incoming goods gate uses thermographic sensors to identify damaged batteries early. This ensures that only undamaged batteries are stored in the warehouse.

Efficiency

With its automated processes, our incoming goods gate optimises procedures, accelerates the admission of batteries into the warehouse and significantly reduces waiting times.

Documentation

The gate photographs the outer condition of the goods upon delivery. This documentation ensures that all visible damage is recorded when the goods enter the warehouse.

Traceability

The gap-free documentation of all incoming goods ensures a precise traceability of every delivery, which is crucial when it comes to responding to return and inventory queries.

Secure your storage space now!

Maximum safety and efficiency

Safety is incredibly important when dealing with incoming goods in battery logistics as damaged or defective batteries are at high risk of causing fires or other hazards. By detecting problems like this early on in the incoming goods area, only safe and intact batteries enter the warehouse and potential risks for the entire warehouse are avoided. The photographic documentation of the outer condition of deliveries when they arrive adds to this safety measure, by facilitating gap-free traceability and the provision of evidence. Not only does this preventative recording ensure greater safety, but it also increases efficiency as it minimises the risk of later complaints or uncertainty.

Time-saving

Accelerated processes thanks to the fully-automated recording.

Process-optimised

With the incoming goods gate, we can minimise any potential sources of error in the documentation.

Transparent

Real-time access to all relevant data for optimal warehouse management.